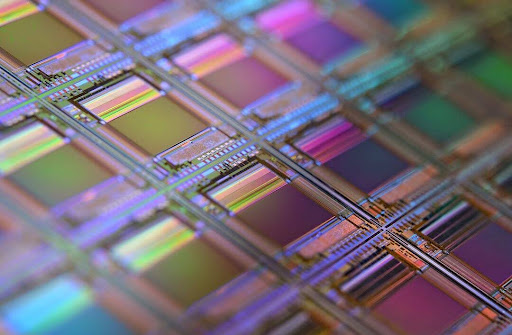

Silicon substrate technology is at the heart of modern electronics. It acts as a fundamental building block for semiconductors. It powers everything from smartphones to supercomputers.

In recent years, there have been groundbreaking advancements in this field. Let’s uncover some of the latest innovations from silicon substrate suppliers.

What is Silicon Substrate Technology?

Silicon substrate technology involves the use of silicon wafers. They are used as a base material for building electronic circuits. These silicon wafers are sliced from a large, cylindrical piece of silicon.

Once sliced, they undergo various processes. They become the foundation for integrated circuits (ICs) and other semiconductor devices.

Silicon is favored for its excellent electrical properties and abundance. This makes it an ideal material for mass production in the tech industry. If you’re looking for more info, check out silybwafers.com/.

Recent Breakthroughs in Silicon Substrate Technology

Modern wafer technology offers many benefits to different industries. Here are a few examples:

Silicon Carbide (SiC) Substrates

SiC is known for its superior thermal conductivity and high breakdown voltage. This makes it ideal for high-power applications. Several industries are leveraging SiC technology to improve efficiency and performance.

Better Heat Management

SiC substrates can handle higher temperatures. It reduces the need for complex cooling systems.

Higher Efficiency

Devices using SiC can operate at higher voltages and frequencies. It leads to improved energy efficiency.

Gallium Nitride (GaN) on Silicon

Another significant innovation is the integration of gallium nitride (GaN) on silicon substrates. GaN is known for its high electron mobility and breakdown voltage. When combined with silicon, it creates a powerful, cost-effective solution. It can be used for high-frequency and high-power applications.

Enhanced Performance

GaN on silicon substrates allows for faster switching speeds and higher efficiency.

Cost-Effective

Using silicon as a base reduces the overall cost compared to using pure GaN substrates.

Thin Silicon Wafers

The introduction of ultra-thin silicon wafers is revolutionizing the semiconductor industry. These wafers are much thinner than traditional ones. They enable more compact and flexible electronic devices.

Flexibility

Thin wafers can be used in flexible electronics. This leads to innovations like foldable smartphones and wearable tech.

Material Savings

Thinner wafers mean less silicon is used. This reduces material costs and waste.

SOI (Silicon on Insulator) Technology

This involves placing a thin layer of silicon on top of an insulating layer. This innovation reduces parasitic capacitance. It increases the speed and efficiency of electronic devices.

Improved Speed

SOI technology enables faster processing speeds. It is crucial for high-performance computing.

Lower Power Consumption

Devices built with SOI consume less power. This makes them ideal for battery-operated gadgets.

3D Silicon Integration

3D silicon integration is a process where silicon wafers are stacked. They are also interconnected vertically. This allows for more functionality in a smaller footprint.

Increased Density

Stacking wafers increases the transistor density. It improves performance and reduces size.

Enhanced Functionality

Different layers can perform different functions. This leads to more versatile and powerful chips.

AI and Machine Learning in Silicon Manufacturing

These technologies help in optimizing the production process. It predicts defects and ensures higher quality.

Process Optimization

AI algorithms can optimize each step of the manufacturing process. It improves yield and reduces costs.

Defect Prediction

ML models can predict potential defects in the wafers. This allows for proactive measures to ensure quality.

The Impact of These Innovations

These advancements are driving the next wave of innovation in the electronics industry. Here’s how:

Enhanced Performance and Efficiency.

New materials like SiC and GaN allow for devices that are faster. They can be more efficient and capable of handling higher power. This is crucial for applications in electric vehicles, renewable energy, and high-performance computing.

Cost Reduction

Innovations like thin silicon wafers help in reducing material costs. This makes advanced technology more affordable. This is particularly beneficial for consumer electronics, where cost is a significant factor.

Smaller and More Versatile Devices

With technologies like thin silicon wafers, devices are becoming smaller. This opens up new possibilities in fields like wearable tech. It also has new applications in flexible electronics and IoT (Internet of Things).

Sustainability

Reducing material usage and improving efficiency contribute to sustainability. For example, thin silicon wafers reduce silicon waste and consume less power. This reduces their environmental footprint.

The Applications of Modern Silicon Substrate Technology

Silicon substrate technology is changing the way we live and work. This might sound like a bold claim, but it’s true. This modern technology has many applications in various fields. From electronics to healthcare, silicon substrates are making incredible advancements possible.

Applications in Electronics

The most well-known use of silicon substrates is in microprocessors. Microprocessors are the brains of computers and smartphones. Integrated circuits are found in almost every electronic device you can think of. Thanks to silicon substrates, these components are becoming smaller, faster, and more energy-efficient.

Another important application is in solar cells. Silicon-based solar cells are the most common type on the market. They convert sunlight into electricity with high efficiency.

Applications in Healthcare

Silicon substrate technology is also crucial in healthcare. Many medical devices use silicon chips. For example, pacemakers and hearing aids rely on silicon-based electronics to function properly. These devices are becoming more reliable and effective.

In addition to medical devices, silicon substrates are used in diagnostic tools. Lab-on-a-chip technology, for example, uses silicon substrates. It uses it to perform complex tests on very small samples.

Applications in Telecommunications

Telecommunications is another field benefiting from silicon substrates. Satellite communication relies heavily on advanced silicon technology. Silicon-based components are used in satellites to ensure clear and reliable communication signals.

The rollout of 5G networks is another exciting application. Silicon substrates play a big role in making 5G technology possible. They help create faster and more reliable network connections. This means better internet speeds and improved connectivity for all devices.

Applications in Automotive Industry

The automotive industry is not left out either. Silicon substrates are key in the development of autonomous vehicles. These vehicles use advanced sensors and computing systems. Silicon-based components make these systems more efficient and reliable.

Electric vehicles (EVs) also benefit. Silicon technology helps improve the performance of EV batteries. This leads to longer driving ranges and shorter charging times.

Know the Latest from Silicon Substrate Suppliers

The field of silicon substrate technology is evolving rapidly. It offers innovations that promise to revolutionize various industries. From high-efficiency power devices to flexible electronics, the possibilities are endless.

For more insights consult your local silicon substrate suppliers. Know how they can benefit you.

For more info subscribe to our newsletter and follow our blog. Let’s build the future together!

Keep an eye for more latest news & updates on Buzz Feed!