Introduction

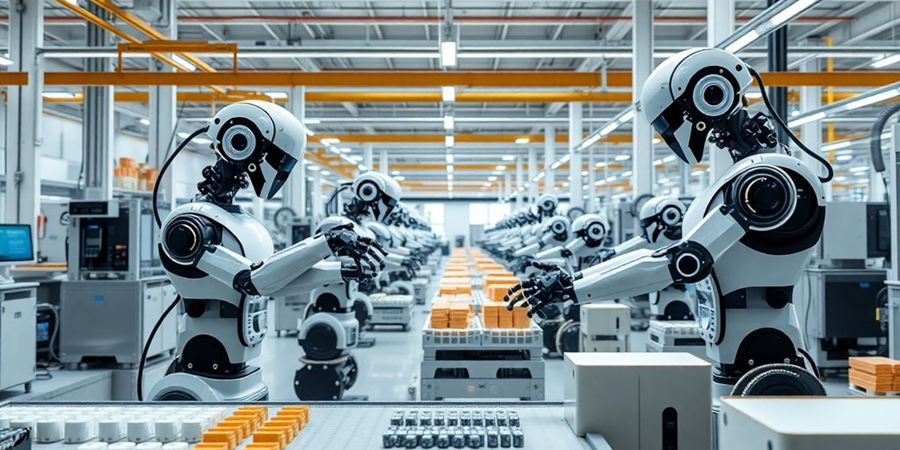

The manufacturing industry is undergoing a radical transformation, driven by the integration of AI and robotics. These technologies are streamlining production, reducing waste, and optimizing operations in ways that were unimaginable just a decade ago. By the end of 2025, AI and robotics will become the backbone of modern manufacturing, enabling higher efficiency, cost savings, and increased adaptability.

According to the Chicagoland Chamber of Commerce, this shift is accelerating at an unprecedented pace. AI and robotics are no longer just buzzwords; they are reshaping how goods are produced and how factories operate.

SO, why does this shift matter? AI and robotics are making manufacturing more sustainable, adaptive, and intelligent.

- AI-powered predictive maintenance prevents breakdowns before they happen.

- Robots handle complex, repetitive, and hazardous tasks, enhancing both safety and efficiency.

- Supply chains become smarter, adjusting dynamically to fluctuations in demand.

Companies that embrace AI and robotics will lead the pack in the coming years. But what does this mean for workers? And how will small and medium-sized enterprises (SMEs) adapt to this new tech-driven landscape?

As we explore this transformation, these are crucial questions to consider.

The Evolution of AI and Robotics in Manufacturing

In the early days, robots were introduced to handle repetitive, manual tasks such as welding, painting, and assembly-line work. These early robots weren’t “smart,” but they were highly efficient, working tirelessly without breaks and drastically improving productivity.

With time, automation systems became more advanced, shifting from mechanical processes to digital automation. This was the foundation of Industry 4.0, where machines began communicating with one another through data-driven systems. These advancements laid the groundwork for today’s AI-powered factories, where manufacturing technology trends focus on efficiency, automation, and real-time data insights.

Now, let’s dive into the most significant advancements that have reshaped manufacturing leading up to 2025.

Advancements Leading to 2025

1. AI for Predictive Maintenance and Quality Control

Imagine your machinery notifying you before it breaks down. AI-driven predictive maintenance does exactly that! By analyzing real-time data, AI can detect anomalies and prevent costly equipment failures before they happen.

Additionally, AI-driven quality control systems use computer vision and machine learning to detect defects in products in real time, ensuring higher accuracy and less waste.

2. Development of Collaborative Robots (Cobots)

Unlike traditional robots, collaborative robots (cobots) work alongside humans, assisting rather than replacing them. Cobots are:

- Flexible and adaptable, adjusting to different tasks.

- Equipped with sensors that allow safe human interaction.

- Enhancing workforce efficiency by reducing manual strain.

With cobots, workers can focus on high-value tasks, while robots handle repetitive or dangerous work.

The integration of AI and robotics is improving efficiency and redefining how manufacturing floors operate. So, how exactly are they transforming production?

The next section talks just about that.

Key Transformations in 2025

1. Enhanced Production Efficiency

- AI-driven analytics optimize supply chains in real-time, reducing bottlenecks.

- Robots complete complex tasks with extreme precision, minimizing errors.

- Smart automation reduces material waste and increases production speed.

2. Improved Product Quality

- Machine learning algorithms predict potential defects before they occur.

- Automated inspection systems ensure high-quality standards.

- Real-time adjustments reduce errors, cutting down on recalls.

3. Workplace Safety Enhancements

- Robots handle hazardous tasks, reducing injury risks.

- AI-driven monitoring systems detect unsafe conditions, preventing accidents.

- Wearable tech and IoT sensors track employee safety in real-time.

With such profound changes, what are the challenges facing businesses in adopting AI and robotics?

Challenges and Considerations

1. Integration Complexities

- Aligning AI-driven robots with legacy systems can be costly and complex.

- Ensuring interoperability between different tech platforms requires investment in new infrastructure.

- Training employees to work with AI systems is essential to maximize productivity.

2. Workforce Adaptation

- Upskilling workers is necessary to keep up with AI-powered systems.

- Job displacement concerns must be addressed through retraining programs.

- Collaboration between humans and robots is reshaping traditional roles in manufacturing.

3. Data Security Risks

- Cyber threats targeting AI-driven factories are increasing.

- Protecting sensitive manufacturing data is critical to maintaining operational security.

- Implementing robust cybersecurity measures is non-negotiable for businesses adopting AI-driven automation.

Despite these challenges, AI and robotics continue to drive the future of manufacturing. What’s next on the horizon?

The Future Outlook

1. Continued Technological Advancements

- Autonomous robotic systems will become even more intelligent and adaptive.

- AI-driven factories will utilize real-time analytics for further efficiency gains.

- Augmented reality (AR) and AI will be integrated into training and production processes.

- The role of AI in manufacturing will continue to expand, with autonomous robots, real-time analytics, and AR-enhanced training becoming standard practices.

2. Industry-Wide Adoption

- AI and robotics will become more accessible to small and medium-sized enterprises (SMEs), making automation affordable.

- The push towards smart factories will continue to shape global manufacturing standards.

- Governments and organizations will promote automation adoption through incentives and subsidies.

Companies that embrace these advancements will gain a competitive edge, leading the way in the next era of industrial innovation.

Conclusion

By 2025, AI and robotics are no longer futuristic concepts—they are redefining how we build, produce, and optimize manufacturing processes.

- Factories are smarter, faster, and safer.

- AI-driven automation is reducing waste and improving efficiency.

- Collaborative robots (cobots) are enhancing productivity while working alongside humans.

However, adapting to these changes requires investment in technology, workforce training, and cybersecurity. Companies that embrace AI and robotics will lead the industry, while those that hesitate risk falling behind.

So, the question isn’t if AI and robotics will transform manufacturing—it’s how fast businesses will adapt.

Are you ready to embrace the future of manufacturing?