PCB Design

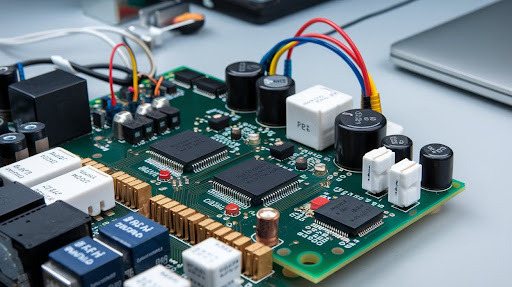

Power Management ICs (PMICs) are super important for modern IoT devices. They help make sure our smart gadgets use power efficiently and don’t run out of battery too quickly. As IoT technology gets more advanced, PMICs become even more crucial. Custom circuit board design is key to making these power-managing chips work their best, which directly affects how well IoT devices function and how long they last. This article will explore why PMIC design and custom PCB layouts are so important for electronic product development, especially in the fast-changing world of IoT.

Key Takeaways

- PMICs are essential for efficient power management in IoT devices

- Custom circuit board design significantly enhances PMIC performance

- HDI PCB design addresses challenges of miniaturization and power efficiency

- Future trends include flexible PCBs, nano-scale components, and eco-friendly materials

- Advanced PCB design is crucial for the continued evolution of IoT technology

What is Power Management IC (PMIC) Design?

PMICs are like the smart power managers of electronic devices. They’re really important for small, energy-hungry gadgets that we use in IoT. These special chips do three main things: they control voltage precisely, distribute power efficiently, and save energy intelligently. When it comes to IoT devices, designing PMICs is tricky because these devices need to be tiny, have different power needs for different parts, and must work well with everything else in the device. It’s also challenging because we need to balance power efficiency with performance, often in small IoT devices that can’t get rid of heat easily.

This is where custom circuit board design becomes super important. By creating circuit boards specifically for each device, we can make sure the PMIC fits perfectly and does its job as efficiently as possible. It’s like tailoring a suit – when it’s made just for you, it fits better and looks great. Custom designs help us put components in the best places, make signal paths shorter, and reduce interference. This approach lets designers use advanced power-saving tricks that are crucial for making IoT device batteries last longer. Plus, custom designs make it easier to add special components that further improve how the device manages power.

The Role of Custom Circuit Board Design in PMIC Performance

Custom circuit board design is like creating a perfect home for PMICs. It helps these power management units work much better. When we carefully plan how everything is laid out and connected, we can make power delivery more efficient, reduce interference, and manage heat better. This is really important for IoT devices because they often work in tough conditions and need to perform well despite being small and having limited power.

For example, if we place a PMIC too far from the parts it powers, it might not work as well. Or if the connections (we call them traces) between the PMIC and other parts aren’t designed right, it could waste power or not deliver enough where it’s needed. By customizing the electronic board design, engineers can make sure everything is just right for each unique IoT device. They can use special techniques to reduce noise, ensure stable power delivery, and make sure signals travel clearly between components. All these improvements help the device use less power, work more reliably, and perform better overall.

Challenges in Electronic Product Development for IoT Devices

Creating electronic products for IoT isn’t easy. There are lots of things to think about. First, these devices need to be small, which means everything inside has to be tiny too. They also need to work for a long time without needing new batteries. And on top of all that, they need to be cheap to make because companies want to sell lots of them. It’s not just about fitting small parts into a small space; we also have to think about heat, signal quality, and making sure different parts don’t interfere with each other. Plus, IoT devices often need to work in all sorts of places, so they have to be tough enough to handle different temperatures, humidity, and physical stress.

PMICs help solve some of these problems. They make sure the device uses power smartly, so batteries last longer. But designing these PMICs and fitting them into IoT devices is still tricky. This is where custom circuit boards come in handy again. By designing the whole board around the PMIC and the device’s specific needs, we can overcome a lot of these challenges. Custom designs let us add advanced power-saving features, improve wireless performance, and even build in security features to protect against hacking. All of this helps make IoT devices that work better, last longer, and are more secure.

Key Considerations in HDI PCB Design for IoT

When designing High-Density Interconnect (HDI) PCBs for IoT devices, there are several important things to keep in mind. These considerations are crucial for creating IoT devices that not only meet the demands of miniaturization and functionality but also ensure reliability, longevity, and cost-effectiveness in production. Let’s explore these key factors in detail:

- Miniaturization: Fitting more components in less space

- Signal integrity: Ensuring clear communication between components

- Power efficiency: Maximizing battery life and performance

- Thermal management: Dealing with heat in compact designs

- Manufacturing feasibility: Ensuring designs can be produced cost-effectively

These factors are crucial for creating IoT devices that are not only small and powerful but also reliable and long-lasting. By focusing on these areas, designers can create HDI PCBs that meet the demanding requirements of modern IoT applications. Miniaturization isn’t just about making things smaller; it’s about finding clever ways to fit everything in, like using tiny holes called microvias. Signal integrity means making sure all the components can “talk” to each other clearly, even when they’re packed close together. Power efficiency is about making the battery last as long as possible while still doing everything the device needs to do. Thermal management is tricky because when you pack a lot of components in a small space, it can get hot, so we need to find ways to keep things cool. Lastly, we have to make sure our designs can actually be made in large numbers without costing too much, which is what manufacturing feasibility is all about.

Future Trends in HDI PCB Design for IoT

The world of IoT is always changing, and HDI PCB design is evolving rapidly to keep pace with these advancements. The future of HDI PCB design for IoT is characterized by innovative approaches that push the boundaries of what’s possible in terms of device functionality, form factor, and sustainability. Here are some exciting trends we’re seeing, which are set to reshape the landscape of IoT device design:

Flexible PCBs

Bendable boards for wearable tech

Nano-scale Components

Even smaller parts for tinier devices

Eco-friendly Materials

Green options for sustainable IoT

These trends are shaping the future of IoT devices, making them more versatile, powerful, and environmentally friendly. As electronic design experts, we’re excited to see how these developments will transform the IoT landscape. Flexible PCBs are like bendy circuit boards that can be used in wearable technology, making it possible to put electronics in clothes and accessories. This opens up new possibilities for health monitoring devices and smart clothes that can adapt to your body. Nano-scale components are super tiny parts that let us make even smaller IoT devices. This is really important for things like medical implants or tiny sensors that can be put in places we couldn’t reach before. Eco-friendly materials are about making electronics in a way that’s better for the environment. This includes using materials that can break down naturally and avoiding harmful substances like lead in solders.

Conclusion

PCB design for High-Density Interconnects (HDI) is a game-changer in the world of IoT. It allows us to create smaller, more powerful devices that can do amazing things. By focusing on custom circuit board design and smart power management, we’re opening up new possibilities for IoT technology. These advanced techniques are helping us make IoT devices that are not just smaller and more energy-efficient, but also capable of doing more complex tasks.

Designing PMICs and HDI PCBs for IoT devices isn’t easy, but with careful planning and creative thinking, we can overcome the challenges. The result is IoT devices that work better, last longer, and can do things we once thought were impossible. As we keep improving materials, manufacturing processes, and design tools, we’re constantly expanding what’s possible with HDI PCBs. This progress is crucial for meeting the changing needs of IoT applications, from better connectivity and security to improved ways of harvesting and storing energy.

The future of IoT looks bright, and it’s built on the foundation of advanced PCB design. As technology keeps evolving, we’ll continue to push the boundaries, creating smarter, more connected devices that make our lives better in many ways. The combination of HDI PCB design with new technologies like artificial intelligence, 5G, and edge computing is going to bring about a new era of IoT innovation. This will lead to IoT systems that can adapt to our needs and the environment around them in real-time. Looking ahead, HDI PCB design will play a huge role in shaping the IoT world, bringing us closer to a future where smart, connected devices are a seamless part of our everyday lives.

Stay in touch to get more news & updates on Buzz Feed!